In the present context must manufacturing companies often adapt to the changing requirements of its customers causing problems in production planning. Internal information systems often are not flexible enough to predict the exact needs and capacity of personnel, equipment, supplies, space, and other values in the case of changes in conditions. In terms of manufacturing enterprise is therefore necessary to have a planning tool which will take account of these changes and provide outputs that will indicate the future behavior of the production system.

In the background, the planning tool are often drawn MTM analysis (and other studies), the results of entering the algorithm of conversion. The role of the user is to specify the input parameters (eg. production program, production batch size, etc.) and will result in the desired outcomes (eg. the need for personnel, staff capacity, etc.)

The tools used in the development of planning tools:

-

STATICAL

Static planning tools provide its user with the ease of a well-known MS Excel. The disadvantage is, above all, that the static tool can not take account of changed conditions of the time and the output is usually only the average value within a certain period of time.

-

DYNAMIC

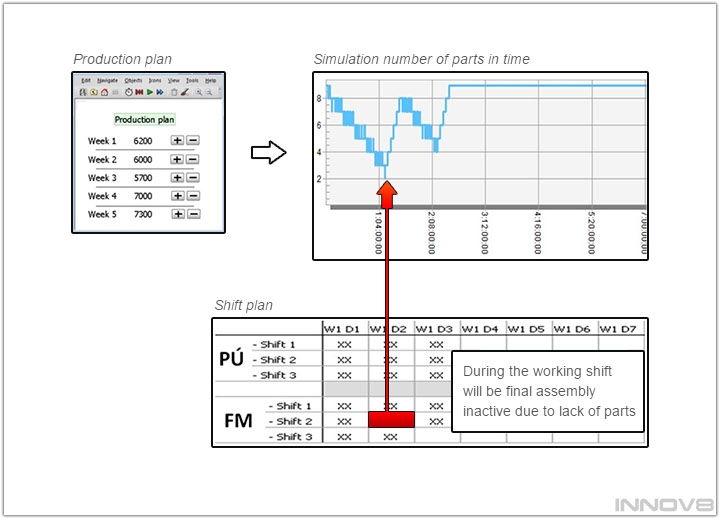

Dynamic so called simulation-based planning tools provide its user with a comfortable view of the behavior of production in each moment. The output of the detailed values, graphs and charts that reflect changed conditions at the time.

STUDY CASE:

Description of project conditions:

To produce the finished product X1 are needed 2 workplaces. Workplace in progress on the first surface treatment parts to subsequently enter the second department in the final assembly. Between institutions of the supermarket. Final assembly is about two times faster than surface treatment and runs only on condition that in the supermarket a required number of finished parts from the previous work. In addition to the product X1 is the aforementioned workplace also produce other products for different customers.

Project objective:

Create a dynamic tool that is designed to plan the structure shifts according to weekly orders X1 product from the customer.

Project benefits:

-

the user of tool has information about when to start or stop individual sites by week plans customer,

-

the user of tool can plan their production to other products of the workplace.