Work measurement represent techniques are focused on process analysis in order to determine the time required in production, logistics and administration.

Currently, at the time "process-oriented enterprises' work measurement plays an integral part of the life cycle of each company. Outputs quantifying activities within the functioning of business processes taking into account their quality characteristics can be used for various assay, planning and optimization activities, which gives the entire system the possibility of constant comparison and improvement are.

Procedure for measurement of work:

- Detailed analysis capacity, repeatability and process conditions.

- Taking into account the required criteria for the award of the project (price, deadline, structure and detail out).

- Selection of the best methods of measuring work.

- Definition of project outputs.

Areas of application outputs of measurements used:

-

Working standards.

-

Monitoring the capacity utilization of staff.

-

Monitoring capacity utilization of techniques.

The methods used for measuring work can be distinguished in the following two groups:

- methods focused on the duration of the process - take into account the TIME parameter as a central feature of the measured activities.

METHODS: multimoments study, time chronometry, video analysis

BENEFITS: time and the economics undemanding

DISADVANTAGES: a high degree of subjectivity,

- The method of content-focused process - take into account all quantitative and qualitative characteristics of the process in the form of pre-determined times, ie codes assigned to each activity.

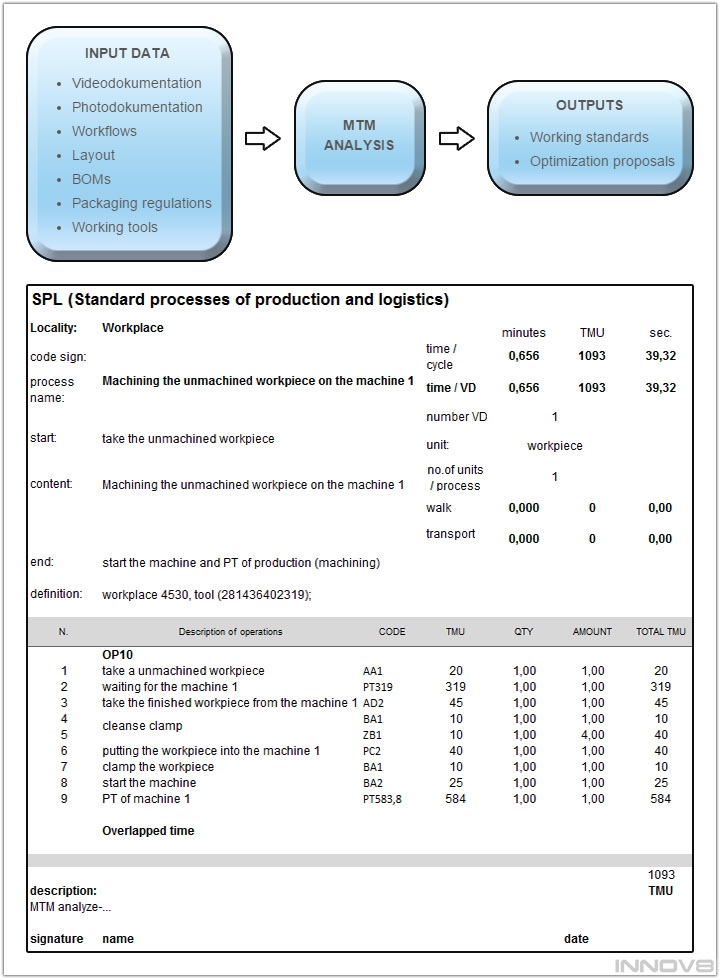

METHODS: MTM 1, MTM-UAS

BENEFITS: objective approach, accuracy, use of the design of future (still existent) processes and their alternatives in the planning stage

DISADVANTAGES: time difficulty

STUDY CASE:

Description of project conditions:

The company took over from its parent company norms on work for the production of individual parts of the final product. The prerequisite was the use of machinery and equipment precisely specified in the standards. However, there were changes in the conditions of implementation process. Purchased or currently used machines and equipment have different parameters and thus the procedure itself works can not be observed for all products. The company continues to use these standards for financial calculations for its existing respectively. potential customers, which in some cases selling products below cost or set too high prices, affecting the acquisition of new contracts.

Project objective:

Update selected existing standards for work using the methodology MTM + identification of optimization proposals.

Project benefits:

-

Detailing of workflow.

-

Clarification of standards for work.

-

Accurate price calculation products.

-

Identification of optimization potentials.