In the present context manufacturing companies must adapt to frequently changing requirements of customers, causing problems in production planning and material flow logistics. Internal information systems often are not flexible enough to predict the exact needs and capacity of staff, number of vehicles, stocks, needs space and other parameters in the case of changes in conditions. From the perspective of the enterprise is therefore necessary to have a planning tool which will take account of these changes and provide outputs that will show future conduct of the logistics system.

In the background of the planning tool are often drawn consumption standards work, timing analysis (and other studies), the results of entering the algorithm of conversion. The role of the user is to specify the input parameters (eg. Production program, production batch size, etc.) and will result in the desired outcomes (eg. The need and capacity of staff, shift calendar, ...).

The tools used in the development of planning tools:

- STATIC

Static scheduling tools provide its user with the ease of a well-known MS Excel. The disadvantage is that the static tool can not take account of changed conditions of the time and the output is the average value within a certain period of time.

- DYNAMIC

Dynamic called simulation-based planning tools provide its user with a comfortable view of the behavior of production and logistics system at any time. The output of the detailed values, graphs and charts that reflect changed conditions at the time.

STUDY CASE:

Description of project conditions:

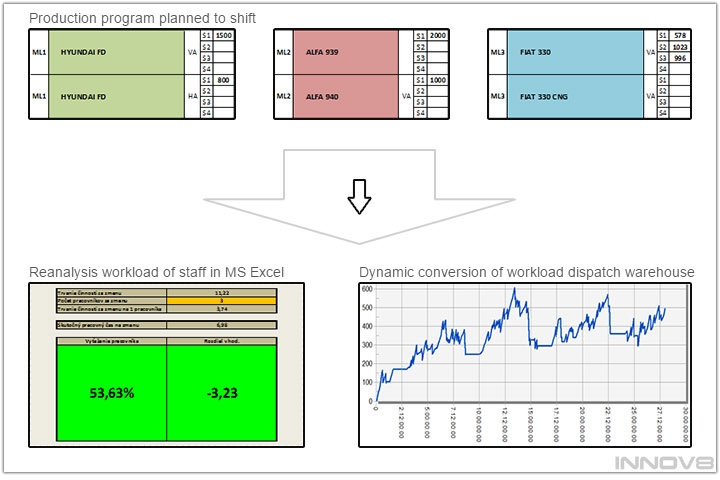

3 assembly lines are supplied empty packaging of a commission area. Assembly lines there are frequent changes in the production program, with the result that there is great variability in folding and preparation of empty packaging on consignment zone. Completed customer packing is then transported from the assembly line to the dispatch warehouse.

Project objective:

- Create a tool to convert the capacity of staff on consignment zone during the work shift, depending on the specified production program.

- Create a tool that would be dependent on the program followed dispatch warehouse capacity.

Project benefits:

- timely information on the need for personnel to a commission area, depending on the specified production program,

- timely information about whether the current capacity dispatch store sufficient, depending on the specified production program.