Warehouses and storage areas are an essential part of business for the entire logistics system. Provide bridging the time when you can not be immediately processed for finished products sent to customers. However, this is an area which has recently been significantly optimized towards reducing the floor space occupied by warehouses. This is mainly due to the increase and expansion of production, when these areas are used more production than stock. Therefore, enterprises in order to get as much space at 0 € investments in the construction of new halls draws on more and more detailed planning and optimization of existing stocks, of course.

In the analysis, planning and optimization stores focus on:

- Storage.

- Layouts.

- Shelving.

- Areas.

- Capacities and stocks.

The methods used in the analysis, planning and optimization of warehouses:

- STATIC METHODS

- ABC analysis

- XYZ analysis

- DYNAMIC METHODS

- PLANT SIMULATION

STUDY CASE:

Description of project conditions:

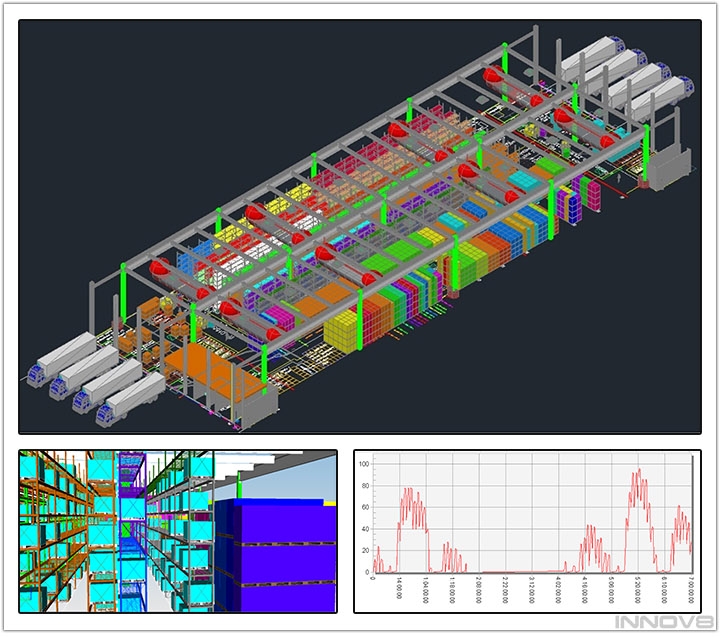

The company decided to build a new hall because existing facilities are not sufficient to cover current needs. In addition, in the near term production expansion plans and part of the storage space will be used as a space for assembly lines. Logistics concept of a new hall and a proposal shelves and storage technology are not planned and the company does not currently have sufficient capacity to create such a detailed proposal. It was therefore decided to cooperate with the company Ltd. INNOV8.

Project objective:

- the design of material flow of finished goods and empty packaging to a new external warehouse,

- spatial analysis and design areas,

- planning analysis based on existing processes,

- calculation of personnel and equipment.

Project benefits:

- simulation model as an optimization and planning tool.